The “robots eat us” is far away for some jobs. In others, that science fiction scenario became a reality a long time ago. Every time it is more common to see that department stores are operated by robots and that automated or remote-controlled machines they have made a space in a framework in which there is a lack of labor. The countryside does not escape from that reality and in a country as dependent on agriculture as Spain, there are already those who are testing self-employed seasonal workers with artificial intelligence who They work tirelessly.

And the controversy is served.

Temporary with AI. A few days ago there was XXX IRTA Fruit Daysa meeting in which agricultural companies present technical innovations for the sector. One of the participants was Moreno Intec del Pla, a distributor and manufacturer of agricultural machinery specialized in fruit harvesting that has to its credit the Tecnofruit: a picking platform with conveyor belts on which human workers manually place the fruit. At this year’s event, the company presented a robot that has been in development for four years.

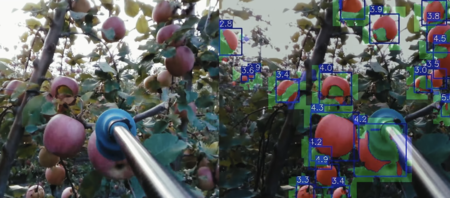

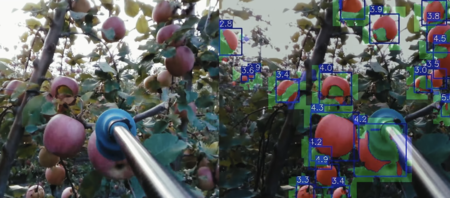

It is a kind of huge container that has the fruit tanks, diesel tank, engine and wheels, but that has eight drones hooked to its upper part. Each of them is armed with an arm that they use to pick up the fruit (apples, in this case) and place it in the containers. The main advantage? They don’t get tired and each unit has integrated lighting to continue working, whatever the time of day.

How it works. Each drone has cameras that allow the specimens to be identified, and a artificial intelligence It is responsible for analyzing whether the piece fits the parameters predefined by the farmer. This system can be configured to harvest all units or to discriminate based on size or color, and although it has remote control so that a single person can control up to five harvesters with the tablet, operation is autonomous.

Apart from harvesting, it can also perform other functions such as the selective elimination of small fruits and, although the system currently uses a diesel engine with the aim of guaranteeing long autonomy, there are plans to create electrified versions.

Costs and labor. Lluís Asín is responsible for the IRTA Fruit Growing program and, as we read in Segrecomments that systems like this represent “an important leap in the competitiveness of the sector.” He states that between 30% and 40% of the production cost of a plantation corresponds to the harvest and that platforms like this can help improve the profitability of the fields.

And, of course, the debate is on the table because the robot arrives to directly replace human labor. Sergi Moreno is the technical director of Tallers Moreno, promoters of this robot, and assures that “it replaces the human part of the process. Each drone acts as if it were a person, but with the ability to operate day and night without rest.”

He continues by pointing out that “the main problem of the sector is the lack of labor at the time of harvest”, but it is not perfect and can be seen in the demonstration video: “the same productivity as in manual work has not yet been achieved.”

Japanese impulse. Now, Moreno is clear that “the future of the field depends on this automation,” and although Tallers Moreno have been the promoters, the robot has the impulse from Kubota Corporation. This is a Japanese agricultural machinery manufacturer that is developing and marketing autonomous drones for fruit and vegetable harvesting. plantation care.

It is not unusual for proposals like this come from Japansince the country is going through a deep birth crisis that is affecting all sectors of society, and work in the field is not left out of this. This automation, in addition to reducing labor costs by 30% (a figure that coincides with IRTA’s estimate), allows increase the height of trees so that they produce more and they claim that the return on investment occurs in just three weeks.

World. The development of this machinery is not isolated and Kubota is working hand in hand with the Israeli company Tevel Aerobotics Technologies. Like many other countries, Israel has a problem with agricultural labor, which is why it is looking to accelerate the development of these autonomous drones. It is one of the epicenters of both development and testing, but there are other countries involved.

- In the United States, states such as California or Washington are already integrating drones in fruit and vegetable harvesting. lettuce.

- In Europe, Italy and Spain have pilot collection programs underway and are also creating development and collaboration platforms, such as Tallers Moreno.

- Chile is evaluating the implementation for apple and grape farms.

Debate. There are other countries in which putting drones to work is being well developed or valued, and the debate is served for the reason you can imagine: it is something that directly replaces the human worker. There are already voices that warn of a future in which the majority of these seasonal jobs will be absorbed by local automation, threatening livelihood of thousands of workers around the world.

Furthermore, there are those who point to a unequal access because it will be the large producers that, with more means, will access this machinery, further strangling the small plantations. There is also the opposite argument, the one that defends robotic labor, pointing that there is no one who wants to work in the field and that new jobs will be created, with people who will have to train to control and maintain these robots.

We continually talk about robots in facilities like car megafactoriesdepartment stores of companies such as Amazon and even in the kitchenbut now the field can be that place where robots perform another silent surprise. Although it will be necessary to see if the collection speed improves, because currently it is far from optimal.

Images | Tevel

In Xataka | You cannot get on the Madrid metro with an electric scooter. In China, robots are already another passenger

GIPHY App Key not set. Please check settings