While Spain does not count With f-35 fighterssoon he will do it with what will be a source of pride for the nation: The Bonifaz frigatefirst of the F110 class, whose launch took place in the navantia shipyards in Ferrol. In fact, Navantia has received a commission that will place her in the world showcase as a reference construction: United Kingdom has asked her to do her Your next frigate. In the background: a plan to become the elite of the sector.

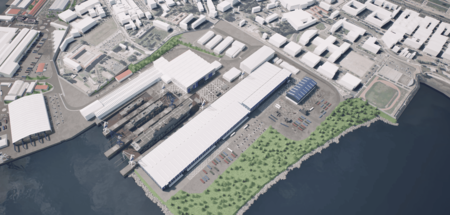

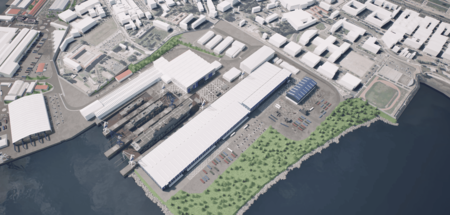

A naval milestone from Spain. Navantia is carrying out in Ferrol the largest investment of the last hundred years in a shipyard in Spain: the creation of the Digital Block Factory (FDB) conceived to place military naval construction in the world technological avant -garde.

With a budget of 110 million eurosan area of 45,000 square meters, 500 meters in length and 90 wide, the plant will double the productive capacity of the Galician shipyard and mark the final step towards the model of shipyard 4.0where automation, artificial intelligence and robotization will be protagonists.

The day. Its inauguration is scheduled for the First quarter of 2026after a construction process that began in March 2024 and has included the creation of a digital twin to monitor in real time the progress of the works, control cost deviations and anticipate failures.

Unpublished productive capacity. The new factory will allow Navantia to manufacture in Only one year the blocks equivalent to a air holder such as Juan Carlos Itwo F-18 frigatesfour European corvettes EPCfour maritime action ships (BAM) or up to two combat supply ships (BAC), in addition to logistical support ships such as the FSS that already produces For the Royal Navy.

In practical terms, the plant may generate simultaneously The blocks of two frigates, with a production cadence of one section every ten days (about 26 per year), which will reduce construction deadlines by 20-25%. In the case of the F-110, about 85% From the structure of each unit it will be manufactured in the FDB, while the singular blocks (such as the dome of the sonar or the multimission mast) will continue to be built in the traditional workshops. This scheme will simultaneously add the commitments to the Spanish Navy and the eventual Export contractsa strategic aspiration in the current context of International Rearme, where the armed demands to have their ships in the shortest possible time.

Automation, AI and Robotics. The factory has been designed under an optimized workflow scheme, divided into three major areas: steels, prearmament and flip. In the first they will be installed Robotized welding lines Equipped with hybrid laser technology, guaranteeing higher structural dimensional precision and robustness. In the prearmament phase, the subblocks will be transferred autonomously by vehicles not manned with IoT sensors, and robots will be integrated for welding, manipulation and palletization that will work collaboratively with the operators.

Finally, in the voltage zone, the blocks will be assembled with subcomponents previously manufactured in an automated assembly system that combines speed, flexibility and reliability. The whole process will be supported by a system of Complete digital traceability: Each piece will generate information associated with its digital twin, which will automatically readjust the following phases and detect real -time deviations using smart cameras connected to 3D models.

The Innovation and Robotics Center. Navantia digital transformation is not limited to the plant itself. He Innovation and Robotics Center (CIR), directly linked to the factory, acts as technological nucleus where the latest innovations in automation, automatic inspection, advanced welding and dimensional control are tested and validated.

The CIR not only develops solutions applicable to immediate production, but also works as Training and Transfer Space of knowledge, ensuring that advances are quickly integrated into productive processes. The ecosystem, reinforced With collaborations With the University of La Coruña and with specialized consultants, it guarantees, a priori, that the Ferrolano shipyard remains on the border of naval innovation.

Labor impact. From the company it has been ensured that, despite the high level of automation, the factory will not involve a template reduction. On the contrary, it will maintain a volume of Between 270 and 400 workers In turn, including both direct employees of Navantia and personnel from auxiliary companies.

In each turn they will operate Between 300 and 325 peopleconfirming that robotization is raised as a tool for support to human capital and not as a substitute. The combination of specialized manual labor and intelligent systems ensures that flexibility is maintained to meet specific demands of each naval program.

Reference at the military plane. Once finished, the FERROL FDB It will not have equivalent in the world of military construction. The only comparable reference is the Alemán Meyer Werft Shipyarddedicated to luxury cruises and has been gradually applying automated systems for fifteen years.

Navantia, however, will be the first company to move this industrial logic War shipswhich, according to the company, will allow you to offer a competitive, sustainable and higher quality product in a sector where the speed of delivery is practically a strategic requirement. In addition, the possibility of producing blocks to Other international shipyardsexpanding his role as a key actor in the global naval supply chain.

New era in the estuary. If you want also, with this bet, Navantia aims to turn Ferrol into a World Reference Pole For military naval construction, combining tradition and modernity in a project that represents a before and after in Spanish industrial history. As Rafael Morgade underlinedresponsible for the digital transformation of the company, it is an authentic “new era” in which the Galician shipyard will go from a disorderly growth accumulated in a century to a concentrated, efficient and technologically advanced model.

In a marked geopolitical context For the rearmethis megafactoría not only reinforces the capacities of the Spanish Navy, but also positions Navantia as a industrial partner in the elite of the international defense market.

Image | Navy

In Xataka | Spain may not have F-35, but it is about to make history by sea: it is called F110 and is ready for any war

GIPHY App Key not set. Please check settings