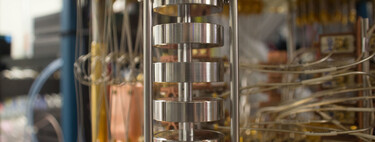

The Interuniversity Microelectronics Center or IMEC (Interuniversity Microelectronics Center) It is not a research center. It is the most experienced laboratory in the tuning of New integration technologies to manufacture integrated circuits and nanotechnology that we have in Europe. In fact, its engineers They work side by side with ASML techniciansTSMC, Intel or Samsung with the purpose of jointly developing new semiconductor packaging technologies or avant -garde photolithography techniques.

This research center is housed in Leuven (Belgium), but in 2030 it will have a new laboratory that will be located in Malaga Techpark, an ambitious technological park installed in this Andalusian capital. José Luis Escrivá, the former Minister of Digital Transformation and Public Function, announced the arrival of Imec to Malaga In January 2024, but a year and a half later we have more important information. According to Malaga today The total cost of these facilities will amount to 615 million euros. The central government will contribute 500 million and the Junta de Andalucía the remaining 115.

On the other hand, the Malaga Center of IMEC will have a total area of 51,300 square meters, and, more importantly, it will use 200 people of high qualification. After all, these researchers will participate in the search for alternatives to the silicon in integrated circuit production processes, as well as in the development of new photolithography technologies that will pursue make possible the manufacture of chips below 1 Nm. However, in addition to these direct jobs, this research center will attract Malaga to other important companies involved in the semiconductor industry.

This is the most ambitious IMEC project: to manufacture 3 angstroms chips

According to Imec In 2035 integrated circuit manufacturers will begin large -scale production of 3 angstroms chips (0.3 Nm). This milestone is very important because presumably these will be the first semiconductors made of the UVE Hyper-á lithography equipment in which ASML is already working. However, of course, these machines will not arrive that year; They will be ready much earlier. That will be the time when Chips manufacturers will start large -scale production, but possibly this machine will be prepared at the end of this decade.

In 2039 chips manufacturers will go beyond the 2 angstroms

Anyway, the interesting thing is that the opening of the optics of these avant -garde lithography equipment will be, again according to IMEC, of 0.75 in the face of the opening of 0.55 UVE UVE MACHINESor 0.33 in Conventional UVE teams. In any case, the itinerary of this laboratory anticipates that In 2037 the integrated circuits of 2 angstroms will arriveand in 2039 chips manufacturers will pass this barrier and go beyond the 2 angstroms.

In the article we dedicate to Rayleight criteria We explain in a lot of detail what the ‘Na’ parameter consists (Numerical Aperture), But in this text it is enough to know that this variable identifies the opening value of the optics used by the lithographic equipment. In this context this parameter essentially reflects the same as the opening value when we talk about The optics of a photo cameraso it conditions the amount of light that the optical elements They are able to collect. As we can intuit, the more light gathens, the better.

Image | Laura Ockel | Wikimedia

More information | IMEC

GIPHY App Key not set. Please check settings